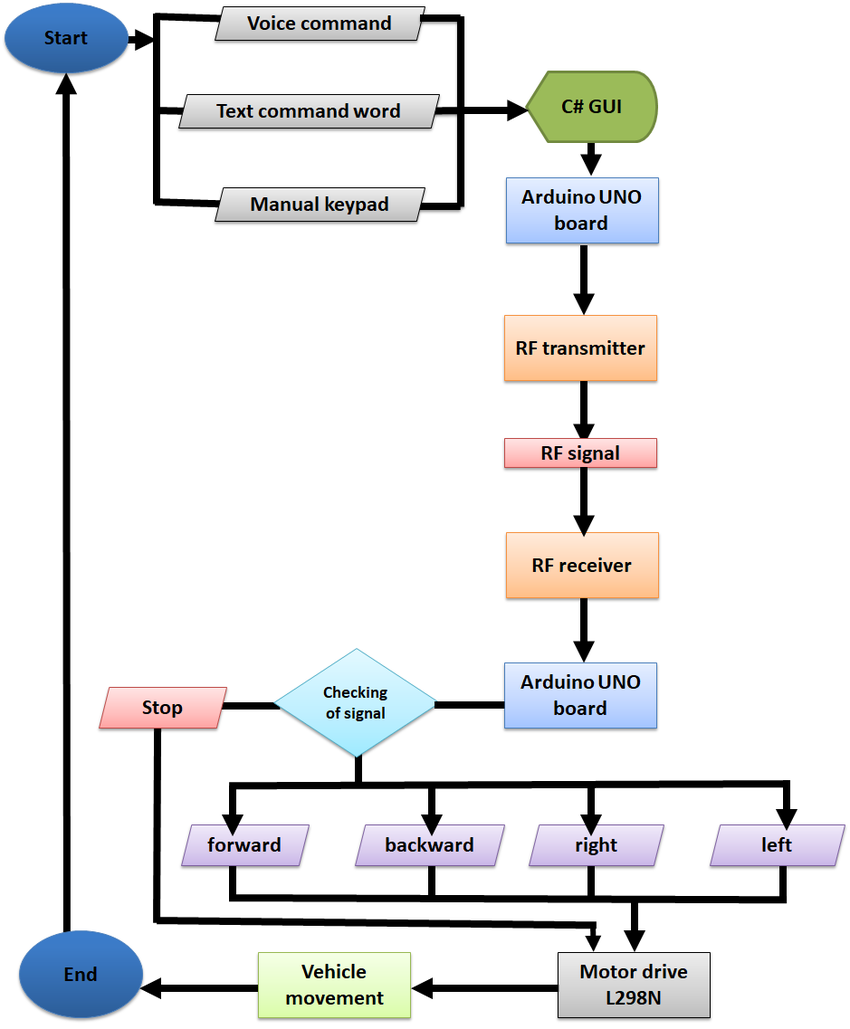

Introduction to Wireless Motor Control

In today's world of robotics and automation, wireless control systems have become increasingly important. This comprehensive tutorial will guide you through creating a Bluetooth-controlled DC motor system using Arduino. Whether you're building a robot, a smart vehicle, or any motorized project, this guide provides the knowledge to implement wireless control efficiently.

Project Overview and Components

What You'll Build

This project creates a system where you can control two DC motors wirelessly using Bluetooth communication. The Arduino board serves as the brain, processing commands received via Bluetooth and controlling the motors accordingly through a motor driver module.

Required Components

To complete this project, you'll need the following components:

Arduino Board

Uno, Nano, or similar microcontroller board

HC-05/06 Bluetooth Module

For wireless communication with smartphones or computers

L298N Motor Driver

Dual H-bridge driver for controlling two DC motors

Two DC Motors

6-12V gear motors recommended for robotics projects

Power Supply

Appropriate voltage and current for your motors (typically 7-12V, 2A)

Breadboard & Wires

For prototyping and connections

Chassis & Wheels

For building a complete robot vehicle (optional)

Battery Holder

To power your mobile robot project

Understanding the Key Components

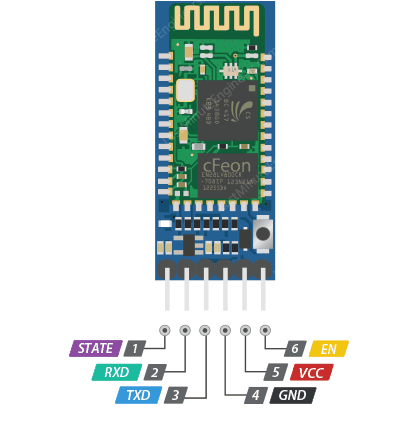

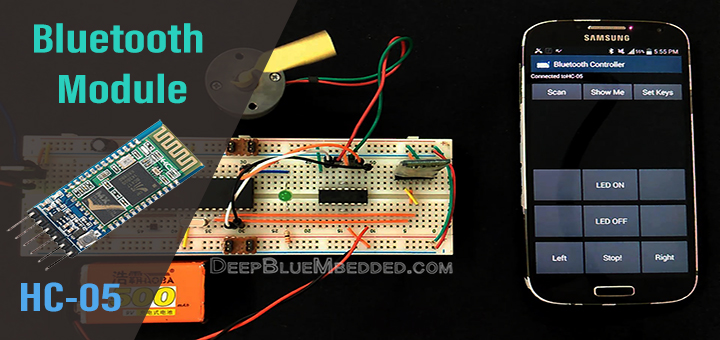

1 HC-05 Bluetooth Module

The HC-05 is a popular Bluetooth module that operates as a Serial Port Protocol (SPP) device, creating a transparent wireless serial connection. It can operate in both master and slave modes, though for this project, we'll use it in slave mode to receive commands from a smartphone or computer.

Key Specifications:

- Operating Voltage: 3.6V - 6V (typically used with 5V)

- Communication: Serial communication at 9600 baud (default)

- Range: Approximately 10 meters (30 feet) in open space

- Pairing: Default pairing code is "1234" or "0000"

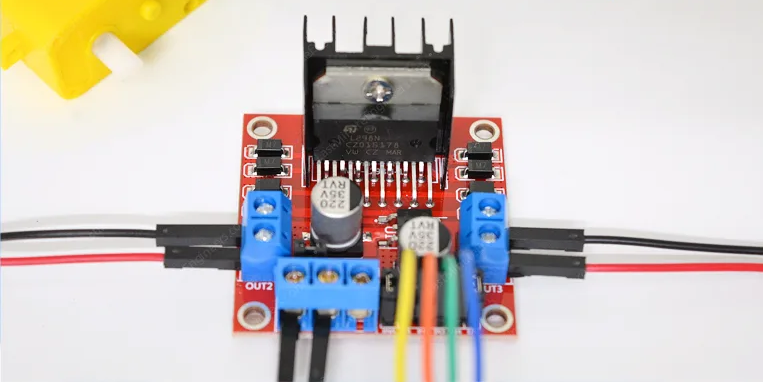

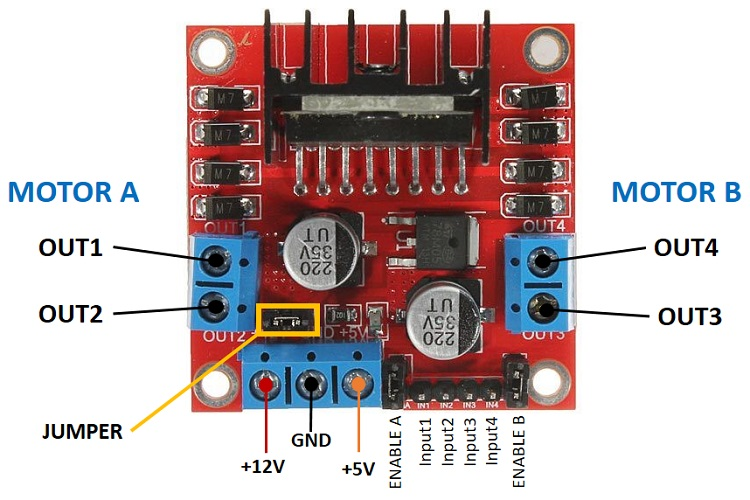

2 L298N Motor Driver Module

The L298N is a dual H-bridge motor driver that allows you to control the direction and speed of two DC motors independently. It can handle significant current (up to 2A per bridge) and includes built-in protection diodes.

Key Features:

- Dual H-bridge design for bidirectional motor control

- Maximum current: 2A per bridge (3A peak)

- Operating voltage: 5V to 35V for motors

- Built-in 5V regulator (can power Arduino with small motors)

- Heat sink and protection diodes included

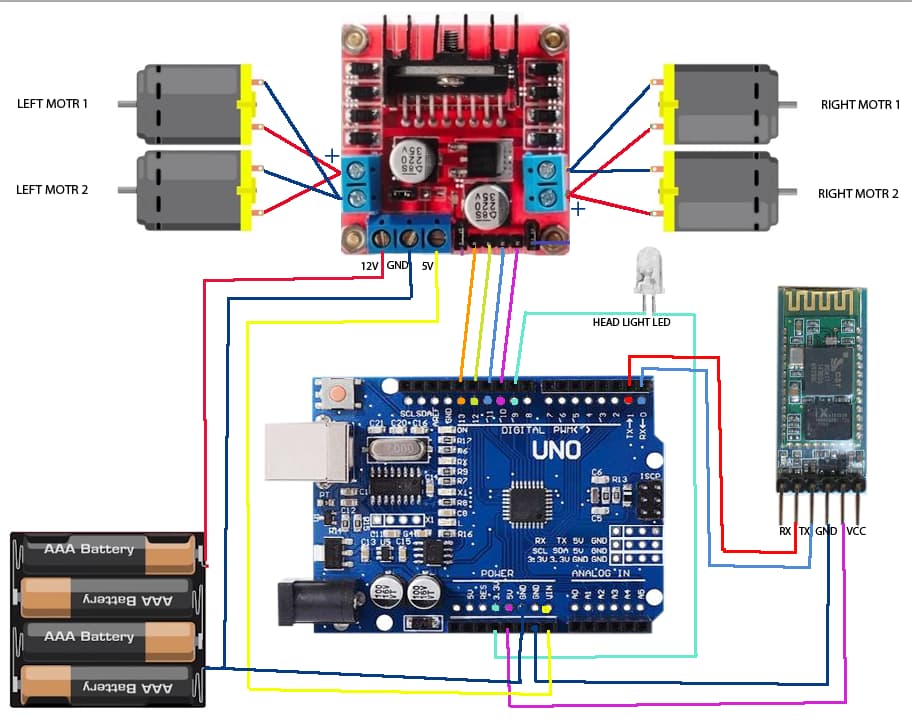

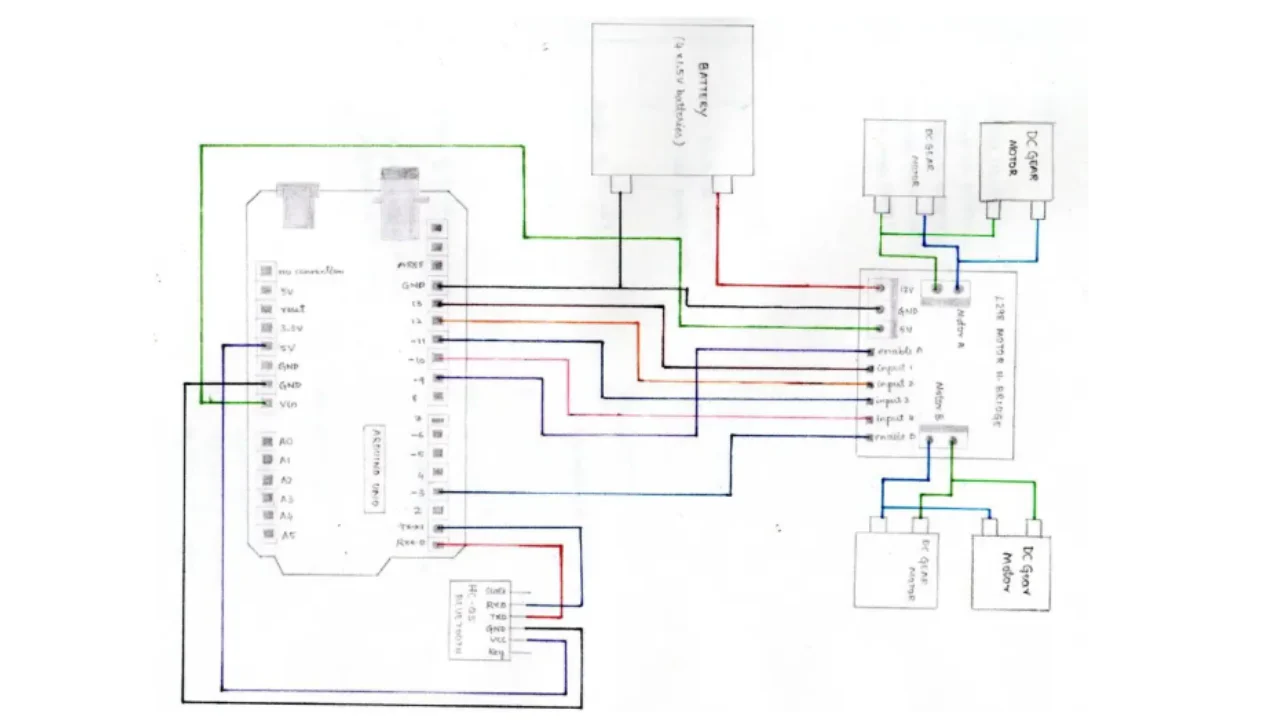

Circuit Connection Guide

3 Step-by-Step Wiring Instructions

Proper wiring is crucial for the success of this project. Follow these connections carefully:

Arduino to L298N Connections:

- Arduino Pin 5 → L298N IN1

- Arduino Pin 6 → L298N IN2

- Arduino Pin 9 → L298N IN3

- Arduino Pin 10 → L298N IN4

- Arduino 5V → L298N +5V

- Arduino GND → L298N GND

Motor Connections to L298N:

- Motor A terminals → L298N OUT1 and OUT2

- Motor B terminals → L298N OUT3 and OUT4

Power Connections:

- External power supply positive → L298N +12V input

- External power supply negative → L298N GND

Bluetooth Module Connections:

- HC-05 VCC → Arduino 5V

- HC-05 GND → Arduino GND

- HC-05 TX → Arduino Pin 0 (RX)

- HC-05 RX → Arduino Pin 1 (TX)

Arduino Code Implementation

4 Complete Control Sketch

Below is the complete Arduino sketch that enables Bluetooth control of two DC motors:

// Define motor control pins

const int motorA1 = 5;

const int motorA2 = 6;

const int motorB1 = 9;

const int motorB2 = 10;

// Variable to store incoming Bluetooth data

char data = 0;

void setup() {

// Initialize motor control pins as outputs

pinMode(motorA1, OUTPUT);

pinMode(motorA2, OUTPUT);

pinMode(motorB1, OUTPUT);

pinMode(motorB2, OUTPUT);

// Initialize serial communication for Bluetooth

Serial.begin(9600);

// Initially stop all motors

stopMotors();

Serial.println("Bluetooth Motor Control Ready");

Serial.println("Send commands: F, B, L, R, S");

}

void loop() {

// Check if data is available from Bluetooth

if (Serial.available() > 0) {

data = Serial.read(); // Read incoming data

Serial.print("Received: ");

Serial.println(data);

// Process the received command

switch(data) {

case 'F': // Move Forward

forward();

break;

case 'B': // Move Backward

backward();

break;

case 'L': // Turn Left

left();

break;

case 'R': // Turn Right

right();

break;

case 'S': // Stop

stopMotors();

break;

default:

// Ignore unrecognized commands

break;

}

}

}

// Motor control functions

void forward() {

digitalWrite(motorA1, HIGH);

digitalWrite(motorA2, LOW);

digitalWrite(motorB1, HIGH);

digitalWrite(motorB2, LOW);

Serial.println("Moving Forward");

}

void backward() {

digitalWrite(motorA1, LOW);

digitalWrite(motorA2, HIGH);

digitalWrite(motorB1, LOW);

digitalWrite(motorB2, HIGH);

Serial.println("Moving Backward");

}

void left() {

digitalWrite(motorA1, LOW);

digitalWrite(motorA2, HIGH);

digitalWrite(motorB1, HIGH);

digitalWrite(motorB2, LOW);

Serial.println("Turning Left");

}

void right() {

digitalWrite(motorA1, HIGH);

digitalWrite(motorA2, LOW);

digitalWrite(motorB1, LOW);

digitalWrite(motorB2, HIGH);

Serial.println("Turning Right");

}

void stopMotors() {

digitalWrite(motorA1, LOW);

digitalWrite(motorA2, LOW);

digitalWrite(motorB1, LOW);

digitalWrite(motorB2, LOW);

Serial.println("Stopped");

}

Bluetooth Control Setup

5 Configuring Your Control Device

Smartphone Control Options:

Android Apps

Serial Bluetooth Terminal, Arduino Bluetooth Controller, or custom apps

iOS Apps

BlueTerm, LightBlue, or Blynk for custom interfaces

Computer Control

Arduino Serial Monitor, CoolTerm, Putty, or custom Python scripts

Custom Interfaces

MIT App Inventor, Blynk, or Android Studio for custom control apps

Pairing Process:

- Power your Arduino circuit

- Enable Bluetooth on your smartphone/computer

- Scan for available devices

- Look for "HC-05" and pair with it (default PIN is "1234")

- Open your serial terminal app and connect to the HC-05 module

Advanced Features and Modifications

6 Adding Speed Control with PWM

To control motor speed, modify the code to use PWM (Pulse Width Modulation) on the enable pins of the L298N:

// Additional PWM pins for speed control

const int enableA = 3;

const int enableB = 11;

// Speed variable (0-255)

int motorSpeed = 150;

void setup() {

// Previous setup code...

pinMode(enableA, OUTPUT);

pinMode(enableB, OUTPUT);

// Set initial speed

analogWrite(enableA, motorSpeed);

analogWrite(enableB, motorSpeed);

}

// Add speed control commands to loop()

if (data == '+') {

motorSpeed = min(motorSpeed + 20, 255);

updateSpeed();

}

if (data == '-') {

motorSpeed = max(motorSpeed - 20, 0);

updateSpeed();

}

void updateSpeed() {

analogWrite(enableA, motorSpeed);

analogWrite(enableB, motorSpeed);

Serial.print("Speed set to: ");

Serial.println(motorSpeed);

}

This modification allows you to control motor speed by sending '+' to increase speed and '-' to decrease speed via Bluetooth.

Troubleshooting Common Issues

Motors Not Moving

Solution: Check power connections, verify motor driver enable jumpers are in place, test motors directly with power supply, check for loose connections.

Bluetooth Connection Issues

Solution: Ensure HC-05 is in pairing mode (LED blinking rapidly), check if module is already paired to another device, verify baud rate matches (9600).

System Resets When Motors Start

Solution: Use separate power supplies for Arduino and motors, add large capacitor (1000µF) across motor power input, check battery voltage under load.

Wrong Motor Direction

Solution: Swap motor wires on the driver outputs or modify code to reverse pin logic in motor control functions.

Project Applications and Extensions

7 Practical Implementations

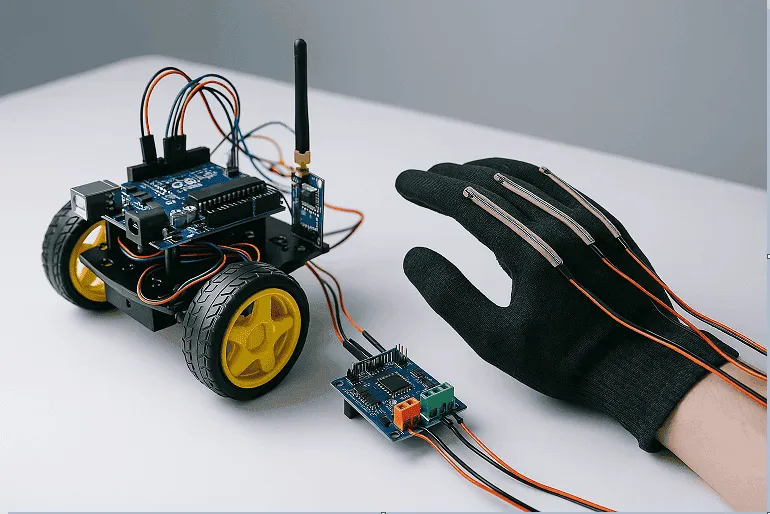

Bluetooth Robot Car

Complete mobile robot with wireless control via smartphone

Smart Home Devices

Control curtains, blinds, or other motorized home fixtures

Educational Demonstrations

Perfect for teaching robotics, programming, and electronics

Assistive Technology

Create devices to help people with mobility challenges

8 Enhancing Your Project

Advanced Project Ideas:

- Wireless Camera: Implement FPV (First Person View) using a Wi-Fi camera module

- Voice Control: Integrate with Google Assistant or Alexa for voice commands

- Autonomous Features: Add ultrasonic sensors for obstacle avoidance

- Internet Connectivity: Add ESP8266 for control from anywhere via the internet

- Multiple Control Modes: Implement joystick control, gesture control, or path recording

Safety Considerations and Best Practices

Electrical Safety

Always double-check connections before powering, use appropriate fuses for motor circuits, keep high-current wiring separated from signal wiring.

Mechanical Safety

Secure all components properly to prevent shorts, add bumpers or sensors to prevent collisions, implement emergency stop functionality.

Thermal Management

Ensure proper ventilation for motor driver modules, monitor temperature during extended use, consider adding heat sinks if needed.

Operational Safety

Test in controlled environments first, keep loose clothing and hair away from moving parts, supervise operation of autonomous systems.

Conclusion

This comprehensive guide has covered everything you need to successfully control two DC motors using Arduino and Bluetooth. From component selection and circuit wiring to programming and troubleshooting, you now have the knowledge to implement this versatile wireless control system in your own projects.

The skills learned here form a foundation for countless robotics and automation projects. As you become more comfortable with these concepts, you can expand your projects with additional sensors, more complex control algorithms, or integration with other technologies like IoT platforms or AI-based control systems.